Custom Engineered Laminates

Custom Engineered Laminates

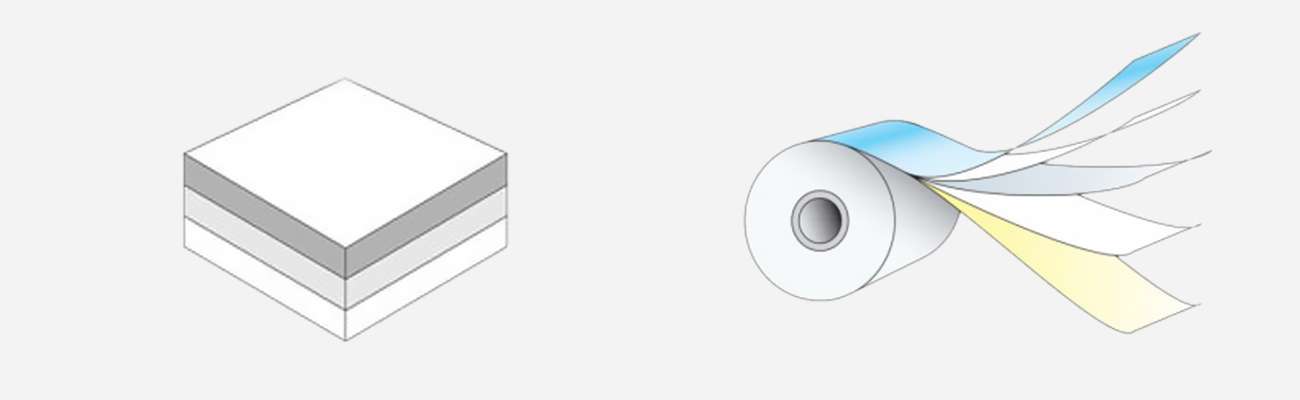

While some flexible packaging manufacturers offer a standard range of materials, we specialize in engineering tailored flexible packaging structures specifically designed for your products. Our expertise in polymer chemistry and flexible packaging engineering allows us to develop cost-effective and superior flexible packaging materials. We work with a wide range of films, foils, papers, and coatings to create customized flexible packaging laminations. A typical flexible packaging structure consists of multiple layers laminated together, with each layer serving a specific function in terms of performance and appearance.

Each layer provides specific performance characteristics, including:

Rigidity

Heat sealability

Print receptivity

Tear resistance

Puncture resistance

Chemical resistance

Opacity or translucency

Glossy or matte appearance

Resistance to oxygen, moisture, or light

Exterior Layer :

Enhances overall pouch strength

Protects the ink and barrier layer

Provides a dimensionally-stable print surface

Contributes to burst strength and tear resistance

Tie Layer :

Conceals the color of the barrier layer

Binds the exterior layer to the barrier layer

Adds an extra layer of protection for the barrier layer

Barrier Layer :

Offers chemical resistance

Prevents moisture, light, and oxygen transmission

Tie Layer :

Provides protection for the barrier layer

Connects the barrier layer to the sealant layer film

Sealant Layer :

Enhances burst strength

Seals the product within the package

Preserves the integrity of the barrier layer

Enables heat sealability of the flexible packaging structure

At our company, we ensure that each layer of our flexible packaging structure is carefully designed to meet your specific requirements and deliver optimal performance

- Laminated Paper

- Laminated Paper for Wrappers

- Polycoated Consumer Paper Packaging Material

- Poly Coated Duplex Board

- PE Coated Light Weight Coated Papers

- Poly Coated Bleached Board

- Reinforced Envelope Papers Poly Coated

- Poly Coated Ivory Paper Board

- Peelable Kraft Poly Coated Lamination Crepe Paper

- Gutkha And Pan Masala Packaging Paper

- Poly-Coated Poster Paper (35 / 40 / 45 / 50 GSM)

- PE Coated Chromo Paper

- Poly Coated Glassine Paper (40 – 41 Gsm)

- Plastic Laminated Kraft Paper (70– 100+ Gsm)

- LDPE Laminated Maplitho Paper (70 – 90 Gsm)

- Poly Laminated Stiffener Paper (80 – 75 Gsm)

- PE Laminated Cup Stock Paper (160 – 250 Gsm)

- PE Coated FBB Board ( Box Folding Board )

- Poly Coated Grey Back Board

- Paper For Sugar Sachet

- BOPP Laminated With Paper

- Metalized Poly With Paper

- 3 Ply Aluminum Laminates

- 4 Ply Aluminium Laminates

- Pet Metpet Poly

- Paper Pe Metpet

- Paper Pe Alu Foils Pe

- PET Alu Foils Poly

- Woven Sack /Non Woven Lamination With Paper

- Flexible Extrusions Laminates Packaging

- Aluminium Foil Laminates

- Other Specialty Coated Laminated Products

- Paper & Paperboards Coating Lamination Products

- Poly Coated Paper Sugar Sachet

- Pharma Packaging Laminated Materials

- PE COATED Al Foil Metpet MetBopp

- Metallic Film Laminated Non-Woven Fabric

- PLY Laminated Foil

- Woven Sack Laminates Products

- PE Laminated Cup Stock Paper

- Food And Baverages Industry

- Tetrapack Laminates

- Custom Engineered Laminates

- Biodegradable Coated Paper & Paper Boards

- PLA Coated Paper & Paper Boards